As a CNC operator, programmer, or machinist, understanding how CNC cutting services work and their capabilities is essential to get your work done. CNC machines are available in different types, each serving a different article. In this article, you’ll learn about CNC cutting services, the types, and the advantages of various CNC cutting machines.

Table of Contents

ToggleWhat are CNC Cutting Services?

CNC cutting services are a form of a subtractive manufacturing method that uses various cutting technologies combined with computer numerical control software to remove excess Sheet metal from blocks and create the needed 2D or 3D shapes.

The most common CNC cutting machines include a water jet, laser, plasma, knife, and much more. CNC cutting services play a vital role in producing quality chemical, aerospace, agricultural, military, automotive, defense, and industrial and commercial products.

Many manufacturers offer CNC cutting services because of their precision, speed, and accuracy with minimal human error. Depending on the purpose and configuration, the CNC cutting process can be done alone or with another process.

Types of CNC Cutting Services

- CNC Plasma Cutting

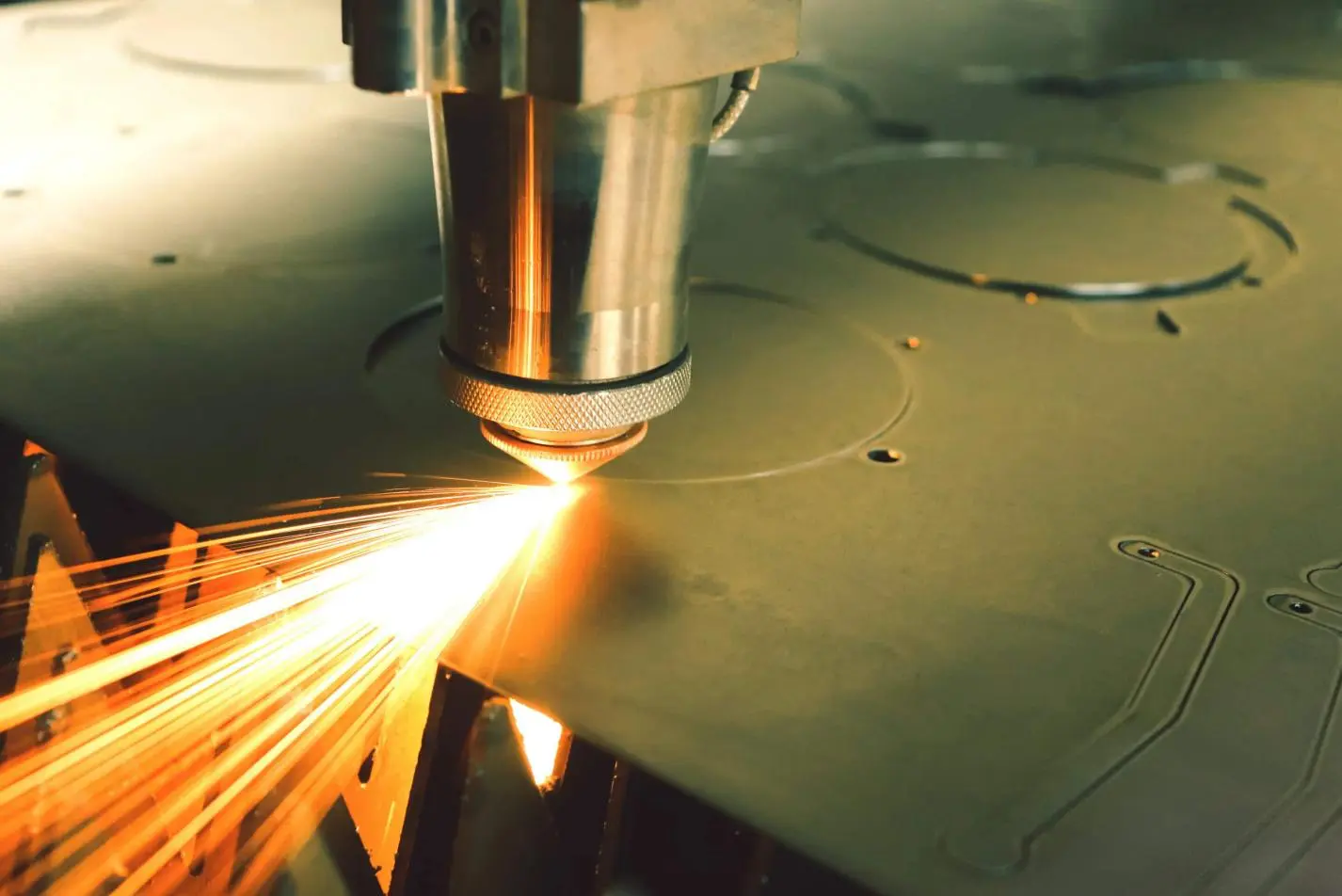

The plasma cutting process involves using a plasma torch to cut heavy materials like mild steel, stainless steel, aluminum, brass, etc. Using a CNC cutter, gas is blown from a nozzle at a very high speed. When this happens, an electrical arc gets formed through the gas coming out to the surface being cut.

Some gas is converted into plasma, and the plasma temperatures are arranged up to 50000 degrees. So, whatever material is cut, the plasma can melt it while blowing away the molten metal from where the cutting is done.

Looking at the size and shape of CNC plasma cutters, they tend to be similar to CNC routers. Also, it’s the most cost-efficient option to opt for. However, plasma cutter machines work with only two-dimensional shapes.

- CNC Laser Cutting

This is a manufacturing process that uses laser cutters to cut a good number of materials, even the hardest gemstones and the toughest metals available. The process tends to be similar to the CNC plasma process, but the difference comes in its usage. CNC laser cutters work best in plastic, cutting metals, or hardwood, creating excellent cutting-edge quality. Depending on the strength and density of the material, laser cutter intensity can be adjusted.

- CNC Waterjet Cutting

This cutting process relies on ultra-high pressure water to carry abrasive grit leaving a smooth and precise cut surface. Waterjet cutting tends to be the most versatile method of cutting almost any material leaving the workpiece with a no heat-affected zone and good surface quality. However, this process is less efficient than laser and plasma cutting techniques.

- CNC milling

This is one of the most common unique CNC machines that use computer controls to cut materials. The mills translate specific programs of letters and numbers to control the spindle in various ways.

CNC milling machines use a standardized programming language called G-code, which most CNC machines use. Compared to other machines, a CNC mill is very large and quite costly. Additionally, a CNC mill has various functions like shoulder milling, face milling, drilling, turning, and tapping. These machines come in 3 to 6- axis configurations.

- CNC Lathe

This is a CNC machine that cuts workpieces once rotated. CNC lathe offers precise cuts through various tools. Besides, its precision is quite effective in precision compared to manual lathes. CNC lathe also has fewer axes than CNC milling machines, thus offering smaller-sized and compact design parts.

Additionally, the CNC lathe contains the same controls as CNC milling. It can read G-code and other programming languages. Ideally, the CNC lathe framework is the same as manual lathes.

- CNC Router

If you have come across a handheld router used to cut various materials, that is the same as a CNC router. This machine can cut through aluminum, steel, plastic, composite, foam, and wood. CNC routers tend to be similar to CNC milling as they can use computer numerical control via the route tool paths that support the functioning of the machine. The advantages of a CNC router include increased productivity and reduced waste by producing multiple items in a shorter time frame than other machines.

What is the difference between CNC cutting services and Laser Cutting services?

The CNC cutting process involves using computer numerically controlled devices and other special tools to produce parts based on the drawing or CAD design provided by clients. The design is then converted to instruction by the CNC machine and guides other operations of tools.

Laser cutting also uses a CNC system to make the laser cutting machine quiet, which relies on heat to help in shaping the workpiece. A high-energy beam cuts through the materials to get the desired geometries.

So what is the difference?

The major difference is how the cut is performed.CNC cutting directly through physical contact while a laser cutter uses a laser to cut through the metal material. Ideally, CNC cutting is achieved by friction, whereas laser cutting involves heat.

When comparing cost-wise, CNC cutting tends to be more affordable than laser cutting, whose costs are contributed by the laser cutter price.

In addition, Laser cutting has an incredible precision and intricacy that’s impossible in CNC cutting. Laser cutting also provides cleaner edges than CNC cutting. The biggest advantage of CNC cutting is its ease of producing curved, diagonal, straight-lined, and other complex shapes easily with CNC programming; CNC cutting eliminates human error.

0