Chinese laser engraving machines have been in existence over the years, proving to be valuable in many industries. Laser engraving machines can cut and engrave various materials. Laser engravers tend to have lower entry-level requirements making them perfect for small business owners. Because of its minimum requirements, laser engraving machine demands have increased.

Because of increased consumer demands, many sellers are marketing their machines online. Most of these machine types are expensive, but Chinese laser engraving machines are the most cost-efficient. They are made of good quality, services, software, and superior lasers. The warranty that helps you save a lot more makes them even more outstanding.

Table of Contents

ToggleWhat is Laser Engraving?

Laser engraving is a type of laser marking process. It’s a process where a laser beam is physically used to remove the material surface, thus making it a unique touch visible. Laser beams tend to act as chisels while incising marks by removing the material’s surface.

In this article, you’ll learn everything about the Chinese laser engraving process and how to find the best laser engraving machine.

Chinese Laser Engraving Machines Process

The laser engraving technology is used for engraving metals like aluminum and steel or other metals exposed to different surface treatments. The uniqueness of this process is that it can engrave 2D codes while maintaining high readability rates after the post-process treatments. These treatments include heat, e-coating, and shotblasting, therefore, addressing complex traceability issues.

Laser engraving sublimates the surface of a material and creates deep crevices. Meaning the surface absorbs enough energy that it changes from solid to gas. A laser engraving machine generates enough energy to achieve sublimation, allowing the surface to reach vaporization temperature in milliseconds. Laser engraving machines are very powerful when looking at the extreme temperatures needed for sublimation.

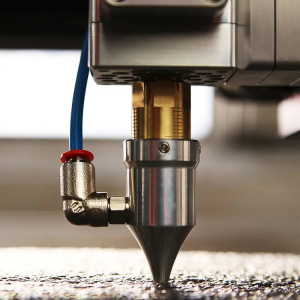

The materials are then vaporized into fumes until they reach the required temperature. A laser machine should come equipped with fume extraction, which protects the work environment, whereas the air knife protects the laser lens. The ideal engraving tool is Fiber lasers because of their capacity to generate wavelengths that react with metals.

0