Belt conveyors are essential pieces of conveyor equipment used across industries to transport materials efficiently. From manufacturing plants to warehouses, belt conveyors have become an indispensable part of material handling systems. This article explores the key components of belt conveyors, the various types available, their design features, and their wide-ranging applications.

Table of Contents

ToggleKey Components of Belt Conveyors

A belt conveyor system consists of several crucial components that work together to ensure smooth operation:

- Belt: The most important component, the belt, is the surface on which materials are transported. It can be made of various materials like rubber, PVC, or metal, depending on the nature of the materials being conveyed and the operating environment.

- Pulleys: These are used to drive the belt and maintain tension. There are typically two types of pulleys: the drive pulley and the tail pulley. The drive pulley is powered by a motor, while the tail pulley helps to return the belt to its starting point.

- Idlers: Idlers support the weight of the belt and the materials being conveyed. They are placed along the length of the conveyor to reduce friction and prevent excessive wear on the belt.

- Motor and Drive Unit: The motor powers the conveyor, and the drive unit transmits this power to the belt. This combination is crucial for maintaining the desired speed and performance of the system.

- Frame: The frame provides structural support to the entire system, holding all the components in place.

- Take-Up System: This component is used to adjust the tension of the belt to ensure smooth and reliable operation.

Types of Belt Conveyors

There are various types of belt conveyors, each designed for specific applications. The main types include:

- Flat Belt Conveyors: These are the most common type of conveyor equipment. They consist of a flat belt and are used to transport lightweight to medium-weight items over short to medium distances.

- Inclined Belt Conveyors: These conveyors are designed to move materials between different elevation levels. They are often used in situations where products need to be lifted to higher or lower levels, such as in mining or recycling operations.

- Cleated Belt Conveyors: These feature vertical or angled cleats on the belt to prevent products from slipping or sliding off. They are ideal for transporting bulk materials like grains, ores, or small items that need to be carried at an incline.

- Roller Bed Conveyors: In these systems, rollers are used instead of a solid belt. They reduce friction and are ideal for moving heavier products or large quantities of materials over long distances.

- Magnetic Belt Conveyors: These conveyors use magnets embedded in the belt to attract ferrous materials. They are typically used in the recycling industry to separate metal objects from other materials.

Design Considerations for Belt Conveyors

When designing a belt conveyor system, several factors must be considered to ensure optimal performance:

Load Capacity: The conveyor must be designed to handle the specific weight of the materials it will carry. Overloading can cause excessive wear and reduce the lifespan of the system.

Speed and Efficiency: The speed at which the belt operates should match the processing needs of the facility. A fast-moving conveyor may be needed in high-throughput environments, while slower speeds may be more suitable for delicate materials.

Environment: The operating environment (temperature, humidity, dust, etc.) affects the choice of materials for the belt, pulleys, and other components. For example, belts made from PVC or rubber are often chosen for environments where moisture resistance is important.

Safety: The design must include safety features such as emergency stop buttons, safety guards, and automatic shut-offs to prevent accidents during operation.

Applications of Belt Conveyors

Belt conveyors are used across various industries due to their versatility and efficiency. Some common applications include:

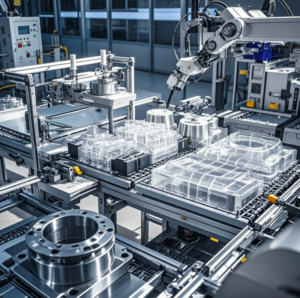

Manufacturing: Belt conveyors are widely used to move raw materials, parts, or finished goods in manufacturing plants, assembly lines, and packaging processes.

Food and Beverage: In the food industry, these conveyors are used to transport raw ingredients, finished products, or even packaged goods. Hygiene and ease of cleaning are important design considerations in these applications.

Mining and Quarrying: Belt conveyors are used to transport ores, coal, and other materials from mining sites to processing facilities.

Logistics and Warehousing: Conveyor equipment is heavily used in sorting and moving goods in warehouses and distribution centers, where high-speed sorting and automated handling are crucial.

Recycling: Conveyor systems are used to move recyclable materials in sorting plants, helping to separate different materials for further processing.

Conclusion

In conclusion, belt conveyors are an essential type of conveyor equipment that play a crucial role in modern industrial and commercial operations. With various types and designs available, they can be tailored to suit specific needs, whether it’s for transporting bulk materials, delicate goods, or heavy machinery parts. By understanding the components, types, and applications of belt conveyors, businesses can optimize their material handling systems, improve efficiency, and reduce operational costs.

0