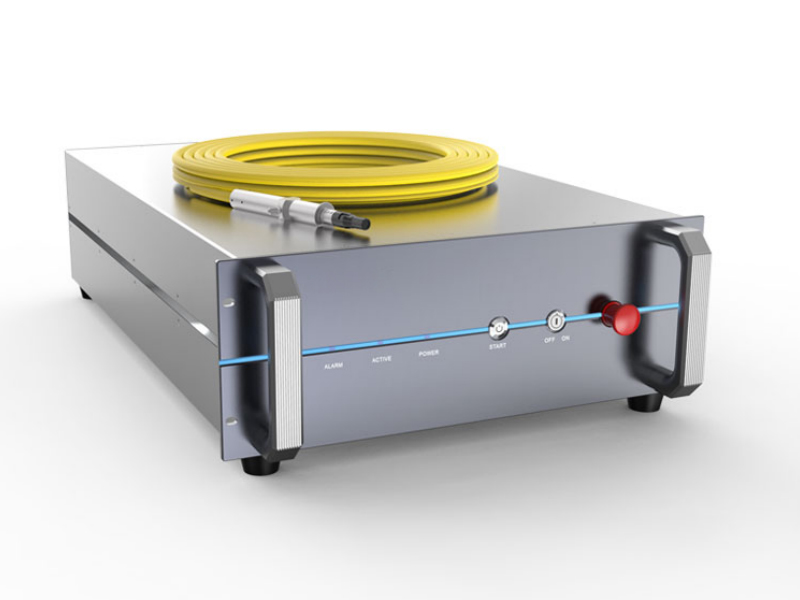

Laser technology, as the core driving force of industrial manufacturing, is also making continuous progress. In general, lasers are developing in four directions “faster, higher, better, and shorter”. Fiber laser machines are used in a wide range of applications, including laser fiber communications, laser space telecommunications, industrial shipbuilding, automobile manufacturing, laser engraving, laser marking, laser cutting, laser cleaning, printing cylinders, metal, and non-metal drilling/cutting/welding, Military national defense security, medical equipment and equipment, large-scale infrastructure construction, etc.

Because there is no optical lens in the resonant cavity of the fiber laser source, it has the advantages of maintenance-free,adjustment-free, and high stability, which is unmatched by traditional lasers.

The fiber output enables the laser to easily cope with various three-dimensional arbitrary space processing applications, which makes the design of mechanical systems very simple. It can withstand harsh working environments and has high resistance to impact, earthquake, dust, moisture, and temperature. No need for water cooling and thermoelectric cooling, only simple air cooling.

Fiber laser machine used in the additive manufacturing and metal cutting markets is expected to continue to grow. Although it is still in its infancy in the additive market, its rapid growth has confirmed this speculation.

With continued improvements in production efficiency and more competitive costs, fiber laser cutting applications will continue to be the economic first choice for manufacturers. This is why fiber laser machines can now enter more application fields and gradually replace the market position of non-laser technologies such as punching, shearing, water jets, and plasma.

High-power fiber laser technology is one of the hottest research directions in the field of optoelectronic technology in recent years, especially in the field of laser technology. It has been widely used in medical treatment, military defense, industrial manufacturing, energy exploration, and other fields.

From the perspective of the development trend of the entire high-power laser industry, fiber laser machines combine the waveguide characteristics of optical fibers and the pumping characteristics of semiconductors, and have excellent advantages such as compact structure, good heat dissipation, high efficiency, good beam quality, and flexible operation.

Table of Contents

TogglePrinciple of Fiber Laser Machine

Fiber amplifiers developed using fibers doped with rare earth elements have revolutionized the field of lightwave technology. Since any optical amplifier can form a laser with the proper feedback mechanism, fiber laser machines can be developed based on fiber amplifiers.

The currently developed fiber lasers mainly use rare-earth element-doped fiber as the gain medium. Because the fiber core of the fiber laser is very thin, it is easy to form a high power density in the fiber under the action of the pump light, resulting in the “number inversion” of the laser energy level of the laser working material.

Therefore, laser oscillation can be formed by appropriately adding a positive feedback loop (to form a resonant cavity). In addition, because the fiber matrix has a wide fluorescence spectrum, fiber lasers can generally be made tunable, which is very suitable for WDM system applications.

Compared with semiconductor lasers, the main advantage of fiber lasers is that fiber lasers have a waveguide structure, which can provide large-capacity pumping, high gain, high conversion efficiency, low threshold, good output beam quality, narrow line width, simple structure, High-reliability characteristics, easy to realize, and optical fiber coupling

Fiber laser uses: fiber laser marking machine in industry

Industrial production requires lasers with small size, quietness, high reliability, and easy manipulation. Fiber lasers are widely favored by people for their compact structure, high light conversion efficiency, short warm-up time, little influence by environmental factors, maintenance-free, and easy coupling with light guide systems composed of optical lenses or optical fibers.

Now, fiber lasers are gradually replacing traditional lasers in the leading positions of laser marking, laser welding, laser cutting, and other fields. In the field of marking, due to the high beam quality and positioning accuracy of fiber lasers, the fiber marking system is replacing the Nd: YAG pulsed laser marking system pumped by carbon dioxide lasers and xenon lamps, which is not efficient.

Fiber laser used in Sensing

Compared to other light sources, fiber lasers have many advantages when used as sensing light sources. First of all, fiber lasers have excellent performance such as high utilization, good adjustability, good stability, compact size, lightweight, easy maintenance, and good beam quality.

Secondly, fiber lasers can couple well with optical fibers, are fully compatible with existing fiber optic equipment, and can conduct all-fiber testing. Fiber sensing based on tunable narrow linewidth fiber lasers is now one of the hottest applications in this field. The fiber laser has a narrow spectral linewidth, an ultra-long coherent length, and fast frequency modulation.

Combining this narrow linewidth fiber laser with a diffuse reflection sensing system enables fiber sensing to achieve ultra-high precision and ultra-long spacing.

Fiber laser used in therapy

Today, most of the lasers used in the clinic are argon ion lasers, carbon dioxide lasers, and YAG lasers, but usually, they have low beam quality, have very large volumes, require huge water cooling systems, and are very difficult to install and maintain. can be supplemented by fiber lasers.

Since water molecules have an absorption peak at 2 μm, using a 2 μm fiber laser as a surgical tool can achieve rapid hemostasis and avoid damage to human body structures caused by surgery.

Fiber Laser used in Communication

Compared with other types of lasers, fiber lasers have nice advantages in heat dissipation, beam quality, volume, layout compactness, and compatibility with existing systems, and are widely used in the field of communications.

The mode-locked fiber laser with rare earth-doped fiber as the gain medium can produce ultra-short optical pulses with a high repetition rate and pulse width in the order of picoseconds or femtoseconds, and its lasing wavelength falls within the optimal window of 1.55 μm for fiber communication.

In the wavelength band, it is the ideal light source for the future high-speed optical communication system. Now, mode-locked fiber lasers with repetition rates of 10 GHz and 40 GHz have been successfully developed. Once this communication network is rolled out, the demand for this type of laser will be enormous.

0