The manufacturing sector continually evolves, and one essential operation that remains at the core of metal fabrication is the metal bending process. This article explores modern techniques and practical considerations that have transformed metal shaping into a precise and efficient discipline. Our discussion covers fundamental principles, technological advancements, and real-world applications, aiming to provide professionals with a balanced and objective perspective on current practices.

Table of Contents

ToggleFundamentals of Metal Forming

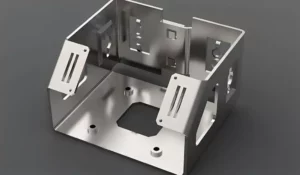

At its core, the metal bending process is a mechanical operation designed to deform metal materials into desired shapes while maintaining their structural integrity. Advances in machinery and software have made it possible to predict and control deformation with high precision. Engineers and fabricators now rely on computer-aided design (CAD) and simulation tools to analyze bending stresses and optimize outcomes, ensuring that components meet both aesthetic and functional requirements. This evolution has contributed to reducing production errors and material wastage, thereby supporting more sustainable manufacturing practices.

Advancements in Technology

Modern approaches to metal forming emphasize automation and quality control. State-of-the-art bending machines are equipped with sensors and feedback systems that monitor force, speed, and temperature in real time. For example, new sensor technology in the metal bending process has revolutionized production by enabling on-the-fly adjustments during operation. Such innovations not only streamline processes but also enhance operator safety by reducing the need for manual intervention in potentially hazardous conditions. The continuous integration of advanced machinery and software tools is paving the way for a more precise and data-driven industry.

Material Considerations and Process Optimization

A deep understanding of the relationship between material properties and bending performance is crucial for any metal shaping task. The selection of metal grades, thicknesses, and tempering conditions directly influences the effectiveness of the bending operation. Materials with high ductility are often preferred for intricate designs, while thicker metals may require specialized equipment to achieve the desired curvature. Manufacturers conduct extensive testing to evaluate the stress-strain behavior of various alloys, ensuring that each bending operation is both reliable and repeatable. This objective approach aligns material choice with practical performance outcomes rather than subjective preferences, reinforcing the importance of data-driven decision-making.

Maintenance and Quality Control

Regular upkeep and calibration are vital to maintaining the integrity of bending operations. A rigorous adherence to the metal bending process ensures consistency and minimizes downtime. Routine maintenance of machinery, including precise calibration and the timely replacement of worn components, is essential for sustaining operational quality. Detailed protocols that document every phase of the operation—from the initial setup to final inspection—are recommended. This systematic approach not only upholds industry standards but also provides a transparent record that supports continuous improvement and long-term reliability in production environments.

Conclusion

The evolution of metal shaping techniques reflects broader trends in industrial efficiency and technological integration. By embracing advanced machinery, sophisticated software, and robust quality control measures, professionals in the field can achieve outcomes that are both innovative and practically applicable. In summary, the metal bending process stands as a cornerstone of modern fabrication, underscoring a commitment to sustainable, data-driven practices. As the industry continues to innovate, the balance between precision, safety, and efficiency will remain key to future advancements.

0