Laser welding is a kind of welding method using a focused laser beam as energy to bombard the heat generated by the weldment. With the continuous upgrading of technology, laser welding technology has made a qualitative leap, and the advantages are becoming more and more obvious.

Because of the optical properties of laser, such as refraction and focusing, laser welding is very suitable for the welding of micro parts and parts with poor accessibility. The machine has been used in many fields, such as medical devices, new energy vehicles, precision machining, hardware, and other fields.

Table of Contents

ToggleWhat are the laser welding advantages?

Good laser beam quality

After laser focusing, the power density is high. The focal spot diameter is smaller after focusing the high-power low-order mode laser.

No need to use electrodes: no concern about electrode pollution or damage.

Laser welding is very suitable for welding precision parts

Because the welding machine has a large aspect ratio, small specific energy, small heat affected zone, and small welding deformation, it is especially suitable for welding precision parts, so post-weld correction and secondary processing are not required, improving work efficiency.

- High flexibility of laser welding

Robot laser welding machines can realize welding at any angle, and can weld inaccessible parts; They can weld various complex welding workpieces and large workpieces with irregular shapes. - Laser welding can weld materials which are difficult to weld

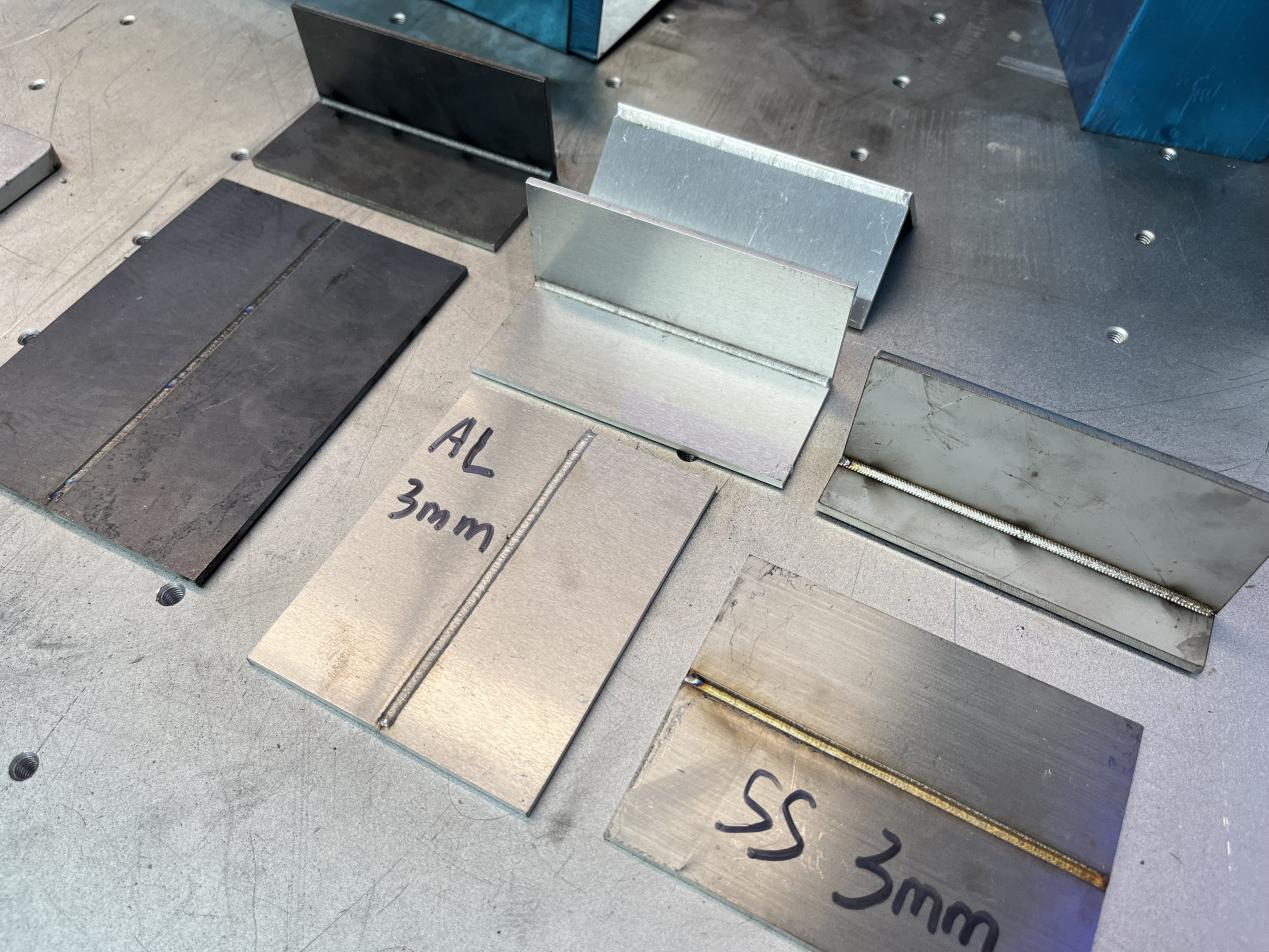

Laser welding can be used not only for welding between various heterogeneous metal materials but also for titanium, nickel, zinc, copper, aluminum, chromium, niobium, gold, silver and their alloys, steels, Kovar alloys, etc. Welding between alloy materials.

- Low labor cost

Due to the extremely low heat input during laser welding, the deformation after welding is very small, which can achieve a very beautiful welding effect on the surface. Therefore, the subsequent treatment of laser welding is very few, which can greatly reduce or eliminate the huge manual work in the polishing and leveling process.

- Simple operation of machine

The laser welding machine has simple welding equipment, a simple operation process, easy to learn, and easy to use. The professional requirements for staff are not high, which saves labor costs.

- Strong safety performance of laser welding machine

Only when the high-safety welding nozzle contacts the metal can it touch the switch effectively, and the touch switch has temperature sensing. There are safety precautions for the operation of the special laser generator. It is necessary to wear laser generator protective glasses during operation to reduce eye damage.

The working environment of laser welding machines is various

Laser welding machines can be welded at room temperature or under special conditions, and can be used in various complex working environments.

The welding quality is slightly inferior to electron beam welding, but the electron beam can only be transmitted in a vacuum, so welding can only be done in a vacuum, while laser welding technology can be more advanced. For a wide range of work environments. This makes the advantages of laser welding more obvious.

These are the laser welding advantages. There are many advantages of laser welding waiting for us to explore. However, laser welders also have certain limitations. Laser welding has not been widely used because of its high price and high one-time investment cost.

In addition, the laser welding machine also requires high installation accuracy of the weldment, and the position of the light source on the commodity workpiece shall not have obvious deviation. It can be seen that the advantages of laser welding machines are much better than traditional welding methods.

0