Laser engraving services have a significant impact on modern technology nowadays. Before knowing laser engraving services, we must understand what laser engraving is.

Laser engraving is a method of engraving permanent, deep marks by vaporizing materials into fumes. The laser beam acts like a chisel, incising patterns by removing layers from the material’s surface. The laser delivers massive amounts of energy to specific areas in order to generate the high heat required for vaporization.

Table of Contents

ToggleHow Do Laser Engraving Services Work?

Whereas laser etching melts the surface of the material to change its roughness, laser engraving sublimates the surface to create deep crevices. This means that the surface absorbs enough energy in an instant to change from solid to gas without ever becoming a liquid.

To achieve sublimation, the laser engraving system must produce enough energy to allow the material’s surface to reach vaporization temperature in milliseconds. Given the high temperatures required for sublimation, laser engravers are pretty powerful.

When purchasing a laser system, it should always include a fume extraction system to protect the work environment and an air knife to protect the laser’s lens. Fiber lasers are ideal for this because they produce a wavelength that reacts well with metals.

What materials can be engraved with a laser?

One of the major benefits of Laser Engraving or laser engraving services is the wide range of materials that can be used. These are:

- Acrylic

- Plywood,

- MDF

- Cardboard

- Glass

- Metal

- Leather

- POM

What Advantages do Laser Engraving Services Provide?

When appropriately used, Laser engraving services provide numerous benefits:

- Quick production process

Laser engraving impresses with its quick turnaround time. Because each laser pulse vaporizes the material, it does not take long to achieve the desired and finished result. Because of the quick process, it is especially useful for rapid manufacturing and when production time is critical. - A diverse range of materials

Another advantage of using laser engraving services is the wide range of materials that can be engraved. Giving the customer flexibility by allowing them to select from various wood options such as MDF, POM or Cardboard, plastic, or metal. These multiple materials allow for design flexibility and freedom. - Precision

Laser engraving has high precision, especially when it comes to small objects like rings or necklaces, and it can engrave complex images into these small objects. - Reliable procedure

The entire laser engraving process is highly dependable. When compared to traditional methods, it almost never results in damaged goods.

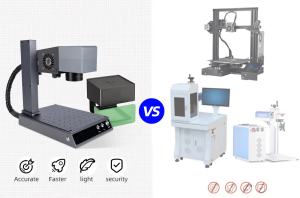

Tips for Purchasing a Laser Engraving Machine

- Concentrate on the primary application: laser engraving or laser cutting.

It’s easy to be swayed by how many other tasks a machine can handle. In almost every way, a good all-rounder is a compromised machine. Just because a machine can cut and engrave does not mean it can do both tasks well. Machines designed for a specific purpose will always perform better than machines designed for a general purpose, so it should come as no surprise that a laser cutter will cut better than a laser engraver and vice versa. - Throughput (the number of parts produced per hour) is almost always the determining factor in commercial success.

Even if your business volume is low right now, production speed is critical. Higher throughput allows you to lower your sales price while increasing your margins, and it also allows you to deliver faster. These three elements are essential to your laser engraving business’s competitiveness, winning, and growth. - Think about the technology first, then the brand.

We frequently see entire workshops outfitted with rows of the same laser engraving machines where the buyer made purchases based on ‘we always buy brand X.’ Brand loyalty has many advantages if a brand can supply the suitable machine for the job. - Purchase from a well-established, reputable supplier who is knowledgeable about both applications and the kit they are selling.

Most machinery suppliers should understand the product they are selling, but this should never be taken for granted. Before making a purchase, challenge the salesperson to demonstrate their understanding of the product, how it works, and, most importantly, their understanding of applications. Don’t settle for a pre-programmed demo that has been tried and tested by the manufacturer.