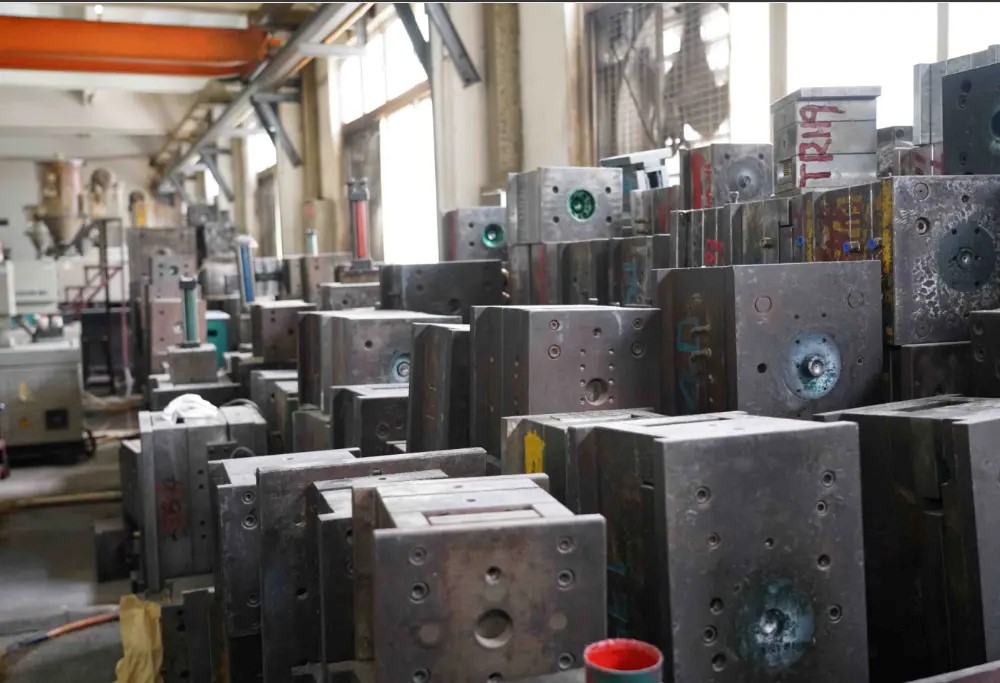

Business sustainability is the practice of running a business without affecting the environment negatively. The process begins with awareness and identifying the issue at hand to finally understanding how important it is to make changes. Having said that, these days, the main focus of the plastic mold manufacturing is to deliver high-quality goods and services in an environmentally sound and sustainable way.

So, let’s dive in and learn more about what it means to be sustainable in plastic injection molding and how manufacturers can be identified that are committed to international standards and sustainability.

Table of Contents

ToggleIs Your Plastic Mold Manufacturing Company Sustainable?

These days, the green movement is most important for every industry. Therefore, it is the duty of every company to make choices and changes that support the environment. When searching for a plastic molding factory, there are several things that can be considered to make sure that you are working with a sustainable and environmentally responsible company.

- Regional and Local Manufacturers

The more the businesses keep their production processes local, the better. It means less wastage and an impact on the environment. It is thus suggested to look for local or regional manufacturers that minimize energy spent on delivery and shipping. Additionally, it offers the benefits of a production facility within easy distance for testing, modifications, and communication.

- Recycled Materials

The material used for plastic injection matters a lot as, during the molding process, excess plastic is eliminated. Make sure you choose a plastic molding factory that minimizes waste by recycling all excessive plastic. Repurposing materials can reduce the need for plastic materials. Resins can be compounded to make new parts. Furthermore, some manufacturers are even exploring and refining processes using plant-based materials.

- Certified Manufacturers

While searching for manufacturers, you can check for ISO 9001. It is the international standard for quality control. The benefits of certified manufacturers are that they constantly strive to improve efficiency and work in an organized process.

- Energy Audit

Automation technology has revolutionized the way we operate machines. The plastic injection machines used in a plastic mold manufacturing company can go a long way toward improving energy efficiency. A few smart investments can result in opportunities to make improvements or renovations that will save energy costs. Such software can be utilized by the manufacturers to monitor machines in real-time and helps in saving energy as they can be shut down when not running.

- Waste Reduction

The manufacturers of plastic parts are committed to waste reduction and thus implement recycling programs in plants. The environmentally friendly plastic molding companies operate state-of-the-art machinery to minimize waste and find support in transportation and packaging. There are also opportunities to repurpose or sell excess resin to third parties. The plastic waste is further reduced from the molding process using high-tech equipment, which transports the excess to a grinder for reuse.

Conclusion

If you want to find a trustworthy plastic mold manufacturing or plastic molding factory, price, delivery speed, quality and service are all factors that must be considered. Only by comprehensively evaluating your own project needs can you finally find the best partner to meet your project.

0