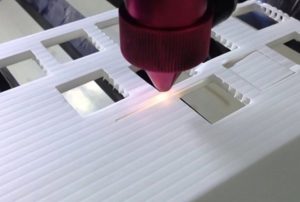

Plastic laser cutting is a fast and economical process of producing high-precision cuts in plastics. This process is applied in most plastics, except the few (e.g., Delrin and Polycarbonate) that have toxic by-products like fumes. In a plastic laser cutter, a CO2 laser with a power rating of over 40W is recommended in a single pass. This is ideal for most plastics, various thicknesses, and specially engineered plastics.

Table of Contents

ToggleConsideration factors for a plastic laser cutter.

- Laser Power

Depending on the type and thickness of the material, a CO2 laser with a power rating of 30W or above is ideal for a plastic laser cutter.

- Cutting Speed

This factor depends on the laser power, thickness, and type of cut material. A slow cutting speed of around 5mm/sec gives good results with smooth edges and a good surface finish.

- Laser Wavelength

A plastic laser cutter with a wavelength of 9.5 µm to 10.6 µm is the best since plastics absorb laser energy within this range. This wavelength can be used for cutting almost all the plastics that are safe for laser processing.

- Exhaust System

Since most plastics generate unpleasant fumes during vaporization by a laser cutter, some fumes can sometimes be harmful to humans. A good exhaust system is required to keep these vapors away from the workplace.

- Air Assist

An air assist in a plastic laser cutter is critical in keeping the temperature under control. A low-pressure air assist is highly recommended since it provides enough time to finish a flame-polished edge.

Types of plastic suitable for laser cutting

The table below is a simple guide to selecting the right and safe type of plastic for laser processing.

| Name of plastic | Plastic-type | Plastic laser cutter features |

| Acrylics | thermoplastic | · Produces non-toxic fumes

· Produces clean flame-polished edge with a superb surface finish · For best results, use a high-power CO2 laser, a wavelength of 10.6 µm, and low cutting speed |

| Fluoropolymers

|

polymer | · Highly resistant to harsh environments

· Produces a clean cut with a good surface finish · A CO2 laser with a wavelength of 9.3 µm to 10.6 µm |

| Delrin or polyacetal.

|

thermoplastic | · A high-strength and rigid plastic material

· Ideal for various applications, e.g., bearings, pumps, gears, etc. · For smooth cuts, use a CO2 laser with a wavelength of 10.6 µm |

| Mylar

|

polyester | · Durable and has a high tensile strength

· Produces smooth cuts with a good surface finish · A CO2 laser with a wavelength of 9.2 µm |

Which is the best plastic laser cutter?

The Laser cutting engraving machine for wood /acrylic /bamboo/plastic with a Laser Type of CO2 glass tube Power supply. The main features include

- Wide processing range

- High operation safety

- HD video and strong picture compatibility

- Strong computer compatibility

- Low power consumption

Conclusion.

By carefully considering factors like laser power, cutting speed, wavelength, exhaust system, and air assist, you can select the optimal plastic laser cutter for your specific needs. Remember to prioritize safety by choosing the right type of plastic and ensuring proper ventilation. With the right setup, plastic laser cutting offers a fast, efficient, and precise way to create a wide range of products.

0